Order Fulfillment for Jewelry

Jewelry is one of the most specialized—and most commonly underestimated—categories in eCommerce fulfillment. At IronLinx, we understand the operational nuance required to handle fashion and lifestyle pieces with care. From secure handling and branded unboxing to SKU complexity and custom packaging, we help brands scale with confidence—whether DTC, subscription-based, or wholesale.

IronLinx offers climate-controlled storage for senstive products.

IronLinx excels at custom pack-out processes and encourages the utilization of branded packaging materials.

Our SaaS-based WMS is robust, fullv

customizable and accessible from any internet-connected device.

Tap into our experience—smart solutions for the operational challenges jewelry brands face every day.

Brand Presentation & Unboxing

At IronLinx, we help jewelry brands create unboxing experiences that reflect the quality and care behind each piece. From branded packaging and custom inserts to tissue wrap, gift notes, and seasonal touches, we execute your vision with consistency and attention to detail. Our fulfillment workflows are built to support both beauty and efficiency—delivering a polished, professional experience at scale. Whether you’re shipping direct-to-consumer, curating subscription boxes, or fulfilling boutique orders, we treat each package with the care it deserves. With years of experience in fashion and lifestyle jewelry, we understand the role presentation plays in reinforcing your brand, deepening customer connection, and building loyalty over time. When every detail matters, IronLinx helps you deliver a complete and compelling customer experience.

Inventory Precision & SKU Management

Jewelry brands often manage hundreds of small, similar items—different metals, finishes, sizes, and packaging styles that make accuracy essential. At IronLinx, we’ve built our fulfillment systems to handle this complexity with care. We support high-SKU operations with detailed inventory tracking, real-time visibility, and strict pick-and-pack controls to prevent errors before they happen. Our team understands how costly a single mistake can be—especially when items are easy to confuse. We also support kitting, variant control, and custom labeling to keep things organized as your catalog grows. Whether you’re fulfilling individual orders or assembling sets for boutiques or subscription boxes, we help you stay in control of your inventory while scaling efficiently. With years of experience supporting lifestyle and fashion jewelry brands, we bring the structure and accuracy you need to operate smoothly, protect your reputation, and deliver the right products every time.

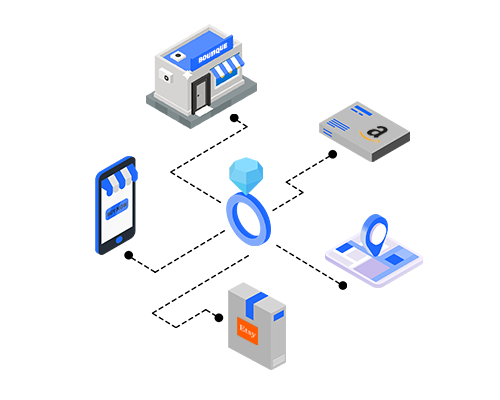

Multi-Channel Scalability

Jewelry brands often sell across multiple channels—direct-to-consumer, marketplaces like Etsy or Amazon, subscription boxes, and wholesale to boutiques. Each channel comes with its own requirements, and managing them all can quickly become overwhelming. At IronLinx, we help streamline multi-channel fulfillment by integrating directly with your sales platforms and routing orders efficiently through a single system. We support custom packaging needs, labeling requirements, and even retail compliance for wholesale shipments. Whether you’re growing your DTC presence or expanding into new channels, our team is equipped to scale with you. We provide the flexibility to test new strategies, add new SKUs, and handle different order types without disrupting your core operations. With deep experience across jewelry fulfillment, we offer the tools and systems to support growth—so you can focus on building your brand, not juggling logistics.

Strategic Support & Operational Insight

Fulfillment isn’t just about packing boxes—it’s about building systems that support your business as it grows. At IronLinx, we provide more than just logistics. We work closely with jewelry brands to help simplify operations, improve workflows, and reduce friction in day-to-day fulfillment. Whether you need help developing a scalable packaging process, understanding shipping costs, or managing inventory more effectively, we bring real-world experience and practical solutions to the table. We also offer dedicated account management, so you always have a direct line to someone who understands your business. For early-stage brands, we act as an operational sounding board. For more established ones, we help streamline complexity and support expansion. Our goal is to be a long-term partner—not just a vendor—so your fulfillment can adapt and grow with your brand.

Jewelry Fulfillment: A Complete Guide for Fashion & Lifestyle Brands

When you sell fashion and lifestyle jewelry, fulfillment is never just about getting orders out the door. It’s about protecting delicate pieces, managing endless variations, delivering a consistent brand experience—and doing it all at scale. From the outside, jewelry might look simple to ship. In reality, it’s one of the most operationally demanding product categories in eCommerce.

At IronLinx, we’ve worked with jewelry brands at every stage of growth—from startup makers on Etsy to established multi-channel sellers. We’ve seen firsthand how fulfillment challenges shift as order volume grows, product lines expand, and customer expectations rise. This guide brings together everything we’ve learned about doing it right.

Inside, we cover what makes jewelry fulfillment so unique and how to build a system that works—whether you’re still fulfilling orders yourself or preparing to transition to a third-party logistics (3PL) partner. You’ll find detailed insights on packaging, shipping, inventory management, tech stack decisions, returns handling, and more.

This guide is written specifically for fashion and lifestyle jewelry brands—those offering affordable, trend-driven, or emotionally expressive pieces across a wide range of styles and SKUs. It’s not intended for high-value fine jewelry or one-of-a-kind luxury items, which often require more intensive handling and security than a 3PL model can support.

If you’re starting to feel the strain of fulfillment—or want to get ahead of it—this guide will help you turn logistics into a competitive strength. It’s built to give you the clarity, structure, and strategic perspective you need to scale your brand without compromising on quality, customer experience, or control.

Table of Contents

- What Is Jewelry Fulfillment?

- Fulfillment That Fits: Matching Your Business Model

- Jewelry Packaging & the Unboxing Experience

- Shipping Jewelry Safely

- What’s Under the Hood: Tech That Scales Jewelry Fulfillment

- Managing Jewelry Returns & Exchanges at Scale

- Scaling Jewelry Fulfillment: From Startup to Established Brand

- Building In-House Fulfillment: What It Takes

- Outsourcing Fulfillment: When (and Why) a 3PL Makes Sense

- Why You Can’t Trust Just Any 3PL

- How to Smoothly Transition to a 3PL

- Ready to Turn Fulfillment into a Strength?

What Is Jewelry Fulfillment?

Jewelry fulfillment refers to the entire backend operation of storing inventory, packing and shipping orders, and managing returns and exchanges on behalf of a jewelry brand. Unlike general product fulfillment, jewelry demands specific expertise in:

- Handling small, fragile, or intricately designed items – Fashion jewelry often involves delicate chains, detailed finishes, lightweight materials, or mixed-media construction. These aren’t products that can simply be tossed into poly mailers or packed by speed-focused warehouse teams. Even affordable pieces require thoughtful handling to prevent tangling, scratching, bending, or breakage. Fulfillment teams must treat every item like it’s part of a larger customer experience—not just inventory moving through a system.

- Managing SKU complexity (e.g. variants by color, metal, size) – Jewelry catalogs often grow quickly. One style can multiply into dozens of variants when you factor in different finishes, lengths, or materials. This SKU complexity adds risk at the fulfillment level—especially when mistakes like shipping the wrong metal or chain length can result in costly returns or lost customer trust. A strong jewelry fulfillment partner understands the pace and structure of trend-based inventories and has systems in place to ensure accuracy at every step.

- Preserving presentation and brand integrity through packaging – For most fashion jewelry brands, packaging is an extension of the product itself. It tells a story, signals quality, and creates a special moment for the customer. But the unboxing experience can fall apart if fulfillment ignores brand details or rushes the packing process. Jewelry requires more than just protection—it needs to arrive styled, aligned, and on-brand. That includes tissue paper, inserts, branded cards, anti-tarnish materials, and thoughtful presentation, all assembled with consistency.

- Preventing damage, tarnish, or loss – Fashion jewelry can be surprisingly vulnerable to wear, tear, and environmental exposure. Improper storage, rough handling, or careless packing can lead to dulling, scratches, and tarnish—especially for plated or mixed-metal designs. Worse, when inventory is disorganized or loosely packed, small pieces go missing. Preventing damage and loss starts with the right shelving, tools, and training—plus a mindset that respects the role of even the most modest component in shaping the customer experience.

In jewelry fulfillment, the product may be small—but the margin for error isn’t. A strong partner understands that every shipment reflects your brand and handles each order with care, consistency, and attention to detail.

Fulfillment That Fits: Meeting the Needs of Your Business Model

It’s easy to treat fulfillment as a backend task. But in jewelry, it’s deeply tied to how your business actually operates. From handmade marketplaces to retail partnerships, your fulfillment setup has to match the pace, complexity, and care your model demands. Here’s how those needs shift based on your brand’s focus—and what that means for your fulfillment strategy.

DTC Jewelry Brands

When you’re shipping direct to consumer, every order is a brand moment. You need consistency, speed, and presentation that reflects your brand voice—whether you’re minimalist and modern or rich with storytelling and color. A fulfillment partner who understands both the product and your customer can help you scale without sacrificing quality or control.

As DTC volume grows, the challenge is maintaining that same unboxing experience at scale. Your DTC fulfillment setup should support:

- Dynamic packaging logic – Different inserts, boxes, or tissue colors based on collection, season, or customer segment.

- Branded add-ons – Loyalty rewards, gift notes, or tiered freebies for repeat buyers or VIP customers.

- Influencer and PR needs – The ability to hand-pack high-touch mailers without disrupting day-to-day fulfillment.

- Error prevention at scale – Barcode scans and verification workflows that minimize mis-picks and returns.

- Agility for seasonal drops – Fast ramp-up for launches, flash sales, or influencer collaborations without missing a beat.

- Fast-turn restocks – Systems and workflows that can handle inventory replenishment with speed, visibility, and minimal downtime.

A one-size-fits-all setup won’t cut it. Your 3PL should feel like an extension of your brand—seamlessly blending operational precision with your customer experience.

Etsy & Marketplace Sellers

Marketplace success can come quickly—and fulfillment is often the first thing to break. As your listings gain traction on Etsy or Amazon Handmade, you move from packing at the kitchen table to needing systems that can keep pace with growing demand. A scalable fulfillment partner helps you meet rising expectations without diluting your identity or slowing your momentum.

As order volume increases, your marketplace fulfillment setup should support:

- Seamless integrations – The ability to connect directly with marketplace platforms like Etsy and Amazon Handmade to automatically import orders, sync inventory, and update tracking—without manual intervention or custom workarounds.

- Structured SKU management – Clear handling of similar-looking or evolving SKUs to prevent mis-picks, especially as your catalog expands with variants or new materials.

- Packaging alignment with brand standards – Consistent presentation of your product regardless of order source, with the option to segment by SKU, collection, season, or channel.

- Inventory buffer zones for oversell protection – Built-in systems that allow for platform-specific inventory reserves, preventing stockouts or order cancellations.

- Gift message and packing slip flexibility – The ability to apply marketplace-branded gift notes or receipts dynamically based on platform rules or buyer preferences.

Growing on marketplaces is exciting—but scaling fulfillment without a partner can drag you into reactive mode fast. The right 3PL gives you the structure to grow intentionally, without losing the qualities that made your brand succeed in the first place.

Boutique & Independent Labels

You’re not trying to become the next mass-market brand—you’re building something intentional. Your collections are curated. Your packaging is customized. And every customer interaction reflects the care you’ve put into your product. Fulfillment needs to operate at that same level—with precision, restraint, and aesthetic discipline.

As your product lines expand and your mix of sales channels grows more complex, your fulfillment partner should support:

- Special handling for delicate pieces – Fulfillment processes designed to protect textured finishes, mixed-media construction, or fragile packaging elements that can’t withstand rough handling.

- Configurable packout logic – The ability to build and apply distinct packout rules by collection, product type, or channel—so the presentation aligns with your brand, not a generic standard.

- Branded packaging and presentation – Storage and consistent application of your gift boxes, tissue, stickers, and collateral—ensuring your unboxing experience looks intentional, not improvised.

- Wholesale-ready order processing – Fulfillment workflows that can handle both small boutique reorders and large, retailer-routed shipments with accuracy, speed, and channel-specific compliance.

- Multi-channel visibility and tracking – Inventory systems that keep stock accurate across DTC, wholesale, and event-based sales without compromising fulfillment flow.

- Quiet growth for curated catalogs – Operational support that keeps pace with growth while respecting the slower, deliberate product cycle of boutique brands.

When your brand is built around intention, fulfillment isn’t just a task—it’s a craft. The right partner keeps your operations as curated as your collections.

Jewelry Subscription Boxes

Subscriptions are a promise. Every shipment must be consistent, well-timed, and on-brand—month after month. Whether your box includes a single hero item or a coordinated collection of pieces, the operational demands behind that experience are high. Fulfillment needs to be structured, repeatable, and error-free—because once the clock starts ticking, you don’t get to hit pause.

To deliver that kind of consistency at scale, your fulfillment partner should support:

- Repeatable kitting workflows – Clearly defined assembly instructions with variant control, quality checkpoints, and built-in flexibility for alternating box configurations.

- Multiple-SKU packouts – Workflows built to combine 2–6 distinct items into a single shipment without manual checking or exception handling.

- Tight inventory synchronization – Real-time stock visibility across box components to prevent mid-cycle shortages or last-minute substitution errors.

- Branded packaging application – Accurate application of box wraps, inserts, filler, tissue, and stickers to protect your visual identity and create a consistent unboxing experience.

- Custom insert rotation – Logic-based insertion of marketing materials, product guides, or printed offers tied to theme, variant, or customer tier.

- Exception-free execution – A structured environment that can manage scale without slippage, even during volume surges, product swaps, or mid-cycle changes.

- Scheduled release coordination – Systems designed to build and hold orders ahead of ship dates, so everything launches on time—even when product is staged in batches.

Subscription fulfillment isn’t just a higher volume of regular orders—it’s an entirely different operational model. A partner who understands that difference can make or break your customer retention.

Wholesale & B2B Jewelry Brands

Wholesale fulfillment demands precision and professionalism. Whether you’re shipping a small reorder to an independent boutique or prepping a PO for a major retail chain, the margin for error is razor thin. Mismatched SKUs, missed ship windows, or packaging that doesn’t meet retail standards can cost you shelf space—or the account altogether. Fulfillment needs to be fast, accurate, and built for compliance.

To meet those expectations, your B2B fulfillment partner should support:

- Channel-aware order handling – The ability to manage wholesale workflows separately from DTC, with different pick logic, packing standards, and documentation.

- Retail compliance – Fulfillment processes that support routing guides, carton labeling, ASN uploads, and branded packaging removal where required.

- Flexible carton and case packing – Configurable packing that supports pre-packs, display-ready cartons, or bulk box distribution without introducing manual workarounds.

- Wholesale-specific pick accuracy – Scanning and verification systems that prevent miscounts or missed line items in large, multi-SKU orders.

- Palletized and LTL-ready shipments – Capabilities for building freight-ready shipments, including case labeling, stretch wrapping, and carrier coordination.

- Integrated purchase order workflows – The ability to accept, process, and reconcile orders by PO number with inventory tracking and order-level traceability.

- Inventory segmentation by channel – Systems that allocate inventory between wholesale, DTC, and other programs without cross-contamination or stockouts.

When B2B fulfillment runs smoothly, it deepens retail relationships and strengthens your brand’s reliability. When it doesn’t, you lose leverage. The right partner helps you deliver with consistency—no matter how complex the order.

Jewelry Packaging & the Unboxing Experience

In jewelry, packaging isn’t just a vessel—it’s the gateway to the product. Before a customer sees what they bought, they see how it is presented. And in a market built on emotion, detail, and giftability, that first impression does more than delight—it defines your brand.

This is where fulfillment becomes visible. Beautiful packaging isn’t just about materials—it’s about how those materials are handled, assembled, and delivered. Execution matters just as much as design.

Why Packaging Matters More in Jewelry

Jewelry customers don’t separate the product from the experience. They expect the unboxing to feel considered and elevated—whether they’re opening a $28 pair of earrings or gifting a $300 necklace. Packaging sets the tone. If it feels careless, the product inside feels diminished.

These expectations are shaped by emotion, not price. Jewelry is expressive, intimate, and often sentimental. Even when the buyer isn’t the recipient, they expect the packaging to represent them—to feel polished, thoughtful, and on-brand without extra explanation.

Trust is built on consistency—and nowhere is that more visible than in packaging. If one package feels special but another arrives flat or thoughtless, trust erodes. In a category built on sentiment and symbolism, consistency is everything. Jewelry brands don’t just compete on design—they compete on the moments they deliver. And packaging defines those moments.

The Building Blocks of Jewelry Presentation

The best packaging is both beautiful and functional. It protects your product during shipping and enhances perceived value upon arrival. Your fulfillment partner must be able to handle the following components with consistency—and execute them flawlessly at scale:

- Custom boxes and mailers — Custom packaging does more than shield your product in transit—it carries your brand into your customer’s hands. Whether you’re using rigid mailers, branded tuck-top boxes, or padded envelopes with your logo, these choices send signals: about quality, about attention to detail, about whether your brand can be trusted. For fashion jewelry in particular, the outer packaging sets the tone before a single piece is seen, but branded boxes and mailers only work if they’re handled correctly. That means assembling them cleanly, using the right packaging for the right product, and avoiding common issues like sloppy taping and labeling.

- Jewelry cards and pouches — Small chains and earrings don’t travel well unless they’re anchored. Jewelry cards, soft pouches, or small plastic sleeves provide a clean way to present pieces while also preventing damage during transport. They keep your pieces flat, separated, and tangle-free—preventing the kind of damage that leads to unnecessary returns. These presentation tools are often brand-specific, so fulfillment teams must know which pieces go with which components and how to handle them without bending, crumpling, or mismatching.

- Tissue paper, stickers, and logo tape — These are the details that take your packaging from functional to thoughtful. When done well, they don’t just protect your jewelry—they create a pause. A soft wrap of tissue sealed with a branded sticker—or an outer box finished with logo tape—creates a moment of anticipation before the jewelry is even revealed. These materials are lightweight and low-cost, but they add real perceived value—especially when they’re consistent with your brand aesthetic. A capable fulfillment partner should treat these details as requirements—not extras. Presentation needs to be executed perfectly, every time.

- Anti-tarnish strips and pads — Tarnish prevention isn’t just for high-end jewelry. Many plated or mixed-metal fashion pieces can dull, discolor, or degrade when exposed to humidity or air either during storage or in transit. Including anti-tarnish materials in your packaging shows care and professionalism—especially for repeat customers who’ve had bad experiences elsewhere. Your 3PL should know when to include these items and how to store and apply them without adding unnecessary cost or complication to your workflows.

- Gift notes and promotional inserts — The insert is where you can speak directly to your customer. It might be a branded thank-you card, a hand-written note, a discount code, or an introduction to your loyalty program. Done right, this step reinforces your voice, strengthens the relationship, and nudges the customer toward their next purchase. Fulfillment teams must handle these materials precisely—not just include them, but match them to the right SKUs, seasons, or campaigns when needed. It’s not a postcard—it’s a critical part of your brand.

These elements aren’t just aesthetic—they’re strategic. Great packaging travels. It gets shared on social media, featured in unboxings, and passed along in gifts—extending your brand’s reach far beyond the first customer. It’s marketing, retention, and customer satisfaction rolled into one.

Operational Support for Branded Packaging

Not every fulfillment center can handle custom packaging at scale. You need a partner who can:

- Store your materials — Custom packaging materials often arrive in bulk and need to be stored carefully to avoid creasing, warping, or contamination. Whether it’s branded boxes, tissue, or insert cards, damage during storage is just as disruptive as damage in transit. Your fulfillment partner should have clear intake procedures, protected storage zones, and accurate counts at all times—so you know what’s available and what’s in use.

- Keep SKUs and variants aligned — Not every item gets the same treatment. A dainty pair of studs might ship in a pouch, while a layered necklace requires a rigid mailer and anti-tarnish strip. Your fulfillment team needs to know which products get which packaging—and have systems that prevent mix-ups. That means mapping SKUs to packaging rules and updating them as your product line evolves.

- Train staff to pack consistently — Even the best-designed packaging can fall flat if it’s packed carelessly or inconsistently. Your 3PL’s team should be trained to follow your exact packing standards—and empowered to notice when something doesn’t look right. Consistency builds trust. A slightly misfolded card or missing sticker may not seem like a big deal—but to your customer, it is.

- Manage seasonal or campaign-specific swaps — Packaging needs change—especially in jewelry. Valentine’s Day gift wrap, holiday inserts, limited-edition materials, or influencer packaging should all be supported without operational chaos. A capable fulfillment partner will plan ahead with you, track material usage, and make smooth transitions between campaigns without interrupting fulfillment or increasing error rates.

- Flag low stock — Running out of branded packaging mid-launch can wreck both presentation and customer trust. Your fulfillment partner should monitor your material levels just like inventory—alerting you when quantities are low and helping you reorder before it becomes a problem. Proactive communication here keeps your brand experience seamless and avoids awkward improvisations.

Beautiful packaging only works if it’s done right. Every detail has to show up exactly as you intended—every time.

Adapting for Gifting and Personalization

Jewelry is one of the most giftable categories in eCommerce—which means fulfillment can’t be one-size-fits-all. Customers expect options: personalized messages, special presentation, and sometimes discreet packaging to keep a surprise intact. These touches are small, but the operational complexity behind them isn’t.

Your fulfillment partner should be equipped to handle high-touch workflows including:

- Custom gift messages — Gift messaging seems simple—until it’s not. Misspell a name, omit a note, or insert it in the wrong box, and what should have been a memorable moment becomes a customer service headache. Your fulfillment partner needs to support gift messaging in a way that’s both flexible and precise, with systems that capture the message at checkout, print it legibly, and insert it into the correct order—without adding bottlenecks or manual workarounds.

- Special presentation workflows — Sometimes your standard packaging isn’t enough. Valentine’s Day, Mother’s Day, or product launches might call for a different wrap, a limited-edition insert, or a premium gift box for high-value customers. These workflows should be planned, documented, and executed without confusion on the warehouse floor. A capable 3PL will handle these seasonal swaps or tiered experiences without missing a beat—and without derailing your fulfillment timeline.

- Discreet packaging — Not every customer wants a branded box showing up on their doorstep. Whether it’s a birthday surprise, a holiday gift, or something more personal, discreet packaging can be a non-negotiable requirement. Your fulfillment partner should be able to recognize and flag these orders automatically—ensuring they ship in plain packaging or without telltale branding, all without requiring special handling requests to be managed manually.

Pulling this off reliably takes more than a flexible pick/pack team. It requires clear communication between your brand and the warehouse, thoughtful documentation, and systems designed to execute personalization without error. If your gifting workflows depend on workarounds, one-off emails, or too much handholding, they won’t scale. A true jewelry-savvy 3PL will make gift handling feel seamless—for you and your customer.

Balancing Cost and Experience

Not every brand can afford the full boutique experience—and that’s okay. Great unboxing doesn’t have to be expensive. What matters most is intentionality and consistency. Even a few well-chosen elements, packed carefully and repeatably, will elevate your customer experience.

Your fulfillment partner should help you find that balance. That includes advising on packaging choices, reducing dimensional weight where possible, and optimizing materials to protect your margins without compromising the experience.

At IronLinx, we benefit from a direct relationship with our sister company, SRILX, which focuses exclusively on packaging materials. That means we don’t just know how to handle packaging—we understand how it’s made, how it performs in transit, and how to make sure it works for your brand. Whether you’re sourcing branded boxes, anti-tarnish supplies, or trying to streamline presentation, we can advise, prototype, and replenish with speed and control most 3PLs can’t match.

Shipping Jewelry Safely: What Fashion Brands Need to Know

Getting the package out the door is only half the job. For fashion jewelry brands, the real question is: Will it arrive intact, on time, and on-brand? Small, lightweight items like earrings, necklaces, and rings are deceptively tricky to ship. They’re fragile, often emotionally significant, and time sensitive. When something goes wrong, the customer’s disappointment cuts deeper than just a delayed delivery.

Why Jewelry Shipping Is High-Stakes

Jewelry shipments come with a unique mix of logistical and emotional risk—and the margin for error is slim.

- Lightweight but delicate – Jewelry may be small, but it’s surprisingly fragile in transit. Lightweight packages are more likely to shift, jostle, or get crushed by heavier items during carrier handling. That means a pair of delicate earrings or a fine chain necklace—no matter how well packed—can emerge bent, tangled, or damaged if not shipped with care. Carriers treat lightweight parcels differently, often tossing them into larger sacks or bins, which increases the chance of damage. Shipping strategies must account for this vulnerability.

- Emotionally charged – Jewelry purchases are rarely just transactional. They mark birthdays, anniversaries, milestones, or quiet personal moments—and customers invest real emotion into the delivery experience. When a piece arrives late, damaged, or missing, it’s more than just an inconvenience; it’s a letdown that can permanently affect brand perception. Shipping errors in this category carry outsized emotional and reputational costs.

- Time-sensitive – Jewelry orders often revolve around meaningful dates—birthdays, holidays, or last-minute gifts. While customers select the shipping speed, it’s the brand’s job to process orders promptly and offer clear, reliable delivery options. Even a small delay can turn an exciting purchase into a missed moment.

In the world of fashion jewelry, shipping isn’t just a logistics function—it’s the final act of a personal, emotional transaction. Brands that treat it with the care it deserves don’t just avoid damage or delays; they build trust, loyalty, and a reputation for getting the important things right—even when a mistake occurs.

Choosing the Right Carrier (and When It Matters)

To your customer, shipping methods don’t feel like operational decisions. They feel like signals. Signals that say: We care. We understand. We’ve got this. The right choice reinforces trust. The wrong one chips away at it.

Standard Options

Your service offerings should help you make deliberate, customer-informed decisions:

- USPS Ground Advantage – USPS Ground Advantage is the go-to option for lightweight, lower-value shipments. It’s affordable, generally reliable, and often delivers within a few days. But as a subordinated service class, it comes with a long tail of unpredictable delays—especially around holidays or during carrier disruptions. In the fashion jewelry space, it’s still a smart play for many orders as the cost savings are real and most packages arrive on time. But there will be outliers, and they’ll frustrate some customers. Brands that use USPS Ground Advantage successfully often set clear expectations upfront and reserve faster methods for time-sensitive or higher-stakes shipments.

- USPS Priority or UPS/FedEx 2Day – When timing matters—whether for a gift, a higher-ticket item, or simply peace of mind—upgrading to a two- or three-day service is usually worth it. USPS Priority balances cost and speed to many (though not all) destinations, while UPS and FedEx 2Day options offer stronger tracking and greater consistency. These methods are especially valuable when a customer is trusting you with a meaningful delivery. They reduce post-purchase anxiety and elevate your brand’s perceived professionalism.

- International Shipping – Cross-border shipping adds layers of complexity—customs, duties, tracking reliability, and longer transit times. That makes carrier selection even more important. Services like USPS First-Class International may be cost-effective, but they often lack end-to-end tracking and can leave customers in the dark. For most fashion jewelry brands, it’s better to choose options with predictable delivery windows and visible tracking—especially for first-time international customers. A higher upfront cost can pay off in trust, satisfaction, and fewer support tickets. When international shipping feels opaque or unreliable, it reflects poorly on your brand, no matter how beautiful the product inside the package.

- Optional Safeguards – Signature confirmation, insurance, or automatic service upgrades can help head off common issues like missed deliveries, damage claims, or chargebacks. Set clear internal thresholds—based on order value, destination, or customer history—and let your shipping logic do the work.

Carriers will get it wrong sometimes—that’s a given. But when your shipping decisions are sound, mistakes stay manageable. A strong mix of service levels, clear rules, and a reliable fulfillment partner keeps those missteps rare—and your brand experience on track.

Dimensional Weight: The Hidden Cost of Branded Packaging

Branded packaging is great for unboxing, but it can quietly sabotage your shipping costs. Bulky presentation boxes increase both actual and dimensional weight, which can trigger higher shipping rates from USPS, UPS, and FedEx.

Cost drivers to keep an eye on:

- Packaging volume creep – It’s easy for packaging to grow over time—new inserts, thicker padding, or slightly larger boxes meant to streamline fulfillment. But even a small increase in dimensions can push a shipment into a higher rate bracket. Dimensional weight pricing penalizes volume, not actual weight, so controlling size creep is key to keeping costs in check.

- Mismatch between packaging and order size – Using oversized packaging for small or single-item orders might feel easier operationally, but it’s expensive in the long run. Sending a single ring or pair of studs in a box designed for a necklace set adds dimensional weight without adding value. A more tailored approach helps preserve both margins and presentation.

- Overlooking flat-rate options for expedited shipping – When speed matters, flat-rate packaging can offer meaningful savings—especially for expedited orders. FedEx and UPS 2Day flat-rate programs let you lock in pricing regardless of actual or dimensional weight, as long as everything fits. That’s a win for jewelry brands—unless your packout is too elaborate to make use of it. Overpacking can push you out of eligibility, turning a cost-saving option into a missed opportunity.

Shipping costs can sneak up on you—not because of distance or speed, but because of how the package is built.

Tracking, Visibility, and Customer Expectations

Jewelry customers expect precision. A missed birthday, a lost anniversary gift, or a “delivered” package that never shows up doesn’t just create frustration—it erodes trust. For jewelry brands, shipping isn’t just a task to complete—it’s part of the brand promise. That’s why tracking, visibility, and fast response times aren’t optional—they’re foundational.

To meet those expectations, your fulfillment team should be equipped to:

- Upload tracking numbers quickly and accurately – The moment an order ships, the customer expects visibility. A delay in uploading tracking—whether by minutes or hours—can spark unnecessary concern and inbound emails. Inconsistent or incorrect tracking adds confusion and damages credibility. Speed and accuracy here aren’t just operational best practices—they’re trust signals.

- Efficiently assist with delivery exception handling – Not every package will arrive without a hitch. Some may stall, misroute, or be marked “delivered” while still in transit. Your system should flag these issues early—while your 3PL plays its part in ensuring claims are started, replacements are sent, and customers stay informed without delays.

Customers don’t care who is technically at fault—the carrier, the fulfillment team, or a porch pirate. If the shipment fails, your brand takes the hit. But when the recovery is handled well, it can absolutely strengthen the relationship.

What’s Under the Hood: Tech That Scales Jewelry Fulfillment

As a jewelry brand grows, so does the complexity behind the scenes. Orders flow in from multiple platforms—Shopify, Etsy, Amazon, and more. Customers expect fast, accurate fulfillment. And you need visibility across everything in real time. That’s where your tech stack starts to matter as much as your product.

Platform Integrations: Your Sales Channels Must Talk to Your Warehouse

Seamless connections between your sales channels and your fulfillment systems are table stakes. If you’re manually importing orders, updating tracking, or syncing inventory across platforms, you’re burning time and inviting mistakes. A modern tech stack integrates directly with the platforms you sell on—automating order flow, syncing updates, and reducing friction at every step.

Your fulfillment setup should support:

- Direct integrations with your sales platforms – Systems that connect with Shopify, Etsy, Amazon, Faire, and others—so orders flow in automatically without the need for CSVs or spreadsheets.

- Automated order routing – Logic that assigns orders to the right warehouse, workflow, or packaging rules based on SKUs, tags, or channel.

- Real-time inventory syncing – Continuous updates between platforms and your WMS to avoid overselling and to simplify restocks across channels.

- Automatic tracking updates – Fulfillment systems that send shipping information back to the right platform instantly, reducing customer service workload.

- Branded notifications and integrations – The ability to trigger platform-specific messaging, tracking emails, or custom delivery flows from within the fulfillment process.

Most of these integrations already exist and are inexpensive to implement. And when they don’t, custom API connections or lightweight middleware solutions are often simpler and cheaper to implement than you might expect.

If your current fulfillment setup can’t support integration—or if you’re relying on duct-taped workarounds—it’s time to upgrade. The tech stack behind your operations shouldn’t be visible to your customers, but it should be powerful enough to keep everything running smoothly.

One Source of Truth for Every SKU

Without centralized inventory, you’re flying blind. When stock is spread across disconnected systems—or worse, managed from memory—you’re inviting stockouts, oversells, and costly delays. A modern fulfillment setup demands a single source of truth that keeps inventory synced across all channels in real time.

Your inventory system should be able to:

- Sync inventory across all channels – Maintain real-time accuracy whether you’re selling on Shopify, Etsy, Amazon, or through your own wholesale portal.

- Track stock movement with precision – Monitor inbound inventory, outbound shipments, and returns in one place—so you always know what’s available and what’s committed.

- Trigger timely replenishment – Set reorder thresholds or receive alerts before key SKUs run low, based on actual movement rather than gut instinct.

- Support kits, bundles, and variants – Properly manage component SKUs so bundled products don’t throw off available inventory or reorder logic.

- Prevent siloed inventory errors – Eliminate the need to reconcile numbers between systems, spreadsheets, or team members manually.

If you’re selling in more than one place, you can’t afford to manage inventory in silos. A centralized system isn’t just about staying organized—it’s about protecting your margin, your brand reputation, and your ability to grow without chaos.

Smart Workflows That Do the Heavy Lifting

As volume grows, automation isn’t just nice to have—it’s the only way to stay efficient. The right tech stack turns fulfillment into a system, not a scramble. Smart workflows keep things moving fast, accurately, and on-brand.

Your fulfillment setup should support:

- Smart order routing – Automatically direct orders to the correct warehouse or fulfillment node based on inventory, region, or order tags.

- Batch processing – Group similar orders for faster picking and packing, improving flow without sacrificing accuracy.

- Custom order tags – Trigger workflows for rush handling, gift wrapping, influencer kits, or manual verification for high-value items.

- Conditional packing rules – Apply logic to pack orders differently based on contents, channel, customer tier, or promotion.

- Operational visibility – Let you monitor workflow triggers and exceptions in real time so nothing falls through the cracks.

When your tech stack supports automation at this level, you don’t have to choose between scale and care—you get both.

Data That Drives Better Decisions

Gut instinct is good—but growth demands data. Real-time operational insight helps you make faster decisions, reduce fire drills, and stay ahead of customer expectations. The right system gives you transparency across your entire fulfillment operation—not just after the fact, but as it’s happening.

Look for a fulfillment partner or platform that enables:

- Live order tracking – See what’s been picked, packed, shipped, or delayed—without relying on emails or manual updates.

- Low-stock alerts and forecasting cues – Get ahead of stockouts with alerts tied to actual movement, not just reorder points.

- Exception reporting – Flag issues early—damaged inventory, missing components, mis-picks—so you can resolve them before they hit the customer.

- Data access across teams – Equip operations, marketing, and customer service with the insights they need to react faster and plan smarter.

Data doesn’t just keep your warehouse running—it supports stronger marketing, better customer experiences, and faster recovery when things go off track.

Managing Jewelry Returns & Exchanges at Scale

Returns in the jewelry category are emotionally charged and logistically tricky. Whether it’s a gift that didn’t land, a size issue, or a change of heart, customers expect a smooth return experience—and brands need a system that protects both presentation quality and profit margin.

Understanding the Real Reasons Behind Jewelry Returns

Returns in the jewelry space aren’t always about defects. More often, they stem from personal preferences and post-purchase emotion—which makes them harder to prevent, but critical to handle well. A streamlined, no-hassle return process doesn’t just reduce friction—it builds trust.

Common triggers and fulfillment considerations include:

- Fit and sizing issues – Rings, bracelets, and earrings are frequently returned when they don’t feel quite right, even if technically accurate.

- Style or design mismatch – Customers may change their minds after seeing the piece in person, especially with bold or distinctive designs.

- Gifting returns – Gift recipients may want to exchange for a different item or return without alerting the giver, which requires discreet processing.

- Unclear return reasons – Jewelry is emotional; some customers simply “don’t love it” and may not explain further—requiring tactful service, not interrogation.

Handled well, returns become a loyalty opportunity. Handled poorly, they undermine the brand. Fulfillment must support the difference.

Protecting Brand Standards on the Way Back In

Every return has to re-enter the system with care. That means more than scanning it in—it requires judgment. Was the packaging opened or torn? Has the item been worn or handled? Is this something you’d feel confident putting in front of a new customer? Jewelry returns are often subjective, and there’s rarely a simple yes/no answer. That’s why your workflow needs to balance efficiency with brand integrity.

A strong restocking process should:

- Inspect packaging and product condition – Catch scuffed boxes, bent cards, or handling wear that could compromise a premium unboxing experience.

- Flag non-resellable returns – Route damaged, worn, or questionable items to separate inventory pools for review, write-off, or rework.

- Preserve ready-to-resell items – Repack items that meet your standards with fresh packaging, so returns don’t lead to unnecessary waste or lost value.

- Capture return reason data – Record subjective issues—like “felt too large” or “didn’t match photo”—to inform future product or merchandising decisions.

- Uphold your brand promise – Apply the same care to returned inventory as you do to outbound orders—because your customer’s next experience depends on it.

Restocking isn’t just a back-office task. It’s a moment of truth where brand reputation, operational discipline, and margin protection all intersect.

The Details That Make or Break Resellability

Unlike clothing or home goods, jewelry is intimate—and condition matters more than most categories. Even minor flaws like bent hooks, smudges, or micro-scratches can make an item unsellable without costly rework. Earrings, in particular, require extra scrutiny due to hygiene concerns. This isn’t just about aesthetics—it’s about trust.

A robust condition check process should include:

- Detailed visual inspection – Review each piece for signs of wear, scuffs, tarnish, or finish flaws—not just whether it looks “about right.”

- Component verification – Confirm that all parts are intact, including hooks, clasps, jump rings, backings, stones, and charms.

- Hygiene-sensitive handling – Follow clear policies for restocking earrings and other sensitive items, with automatic removal or sanitation protocols where needed.

- Packaging assessment – Inspect inner and outer packaging for rips, creases, missing inserts, or residue that could diminish the unboxing experience.

- Rework routing – Send repairable or partially compromised items into a defined rework stream rather than back into sellable inventory.

- Restock criteria enforcement – Apply objective standards that align with your brand promise—not just inventory salvage targets.

Every item that goes back into stock should reflect the same standard you’d expect if you were the customer opening it for the first time. Fulfillment has to enforce that—because once it slips, so does your brand.

Protecting Generosity from Abuse

As you grow, so does the risk of return fraud. From worn items swapped into a return box to false “not delivered” claims, serial returning and policy manipulation can quietly erode your margins—and your confidence. A generous return policy should protect your customers, not leave you exposed.

A strong returns framework should include:

- Monitoring of repeat returners – Track return frequency and value over time to identify patterns that suggest abuse.

- Internal fraud flagging protocols – Define clear criteria for when to hold a return, escalate a case, or temporarily block return privileges.

- Tamper-evident packaging – Use packaging or seals that discourage item swaps or repackaging fraud during the return journey.

- Photo documentation standards – Request product or packaging photos before authorizing returns or resolving disputes involving damage or missing items.

- “Not delivered” claim investigation – Use tracking history, scans, and signature confirmations to verify delivery.

- Policy language that sets boundaries – Communicate your return policy clearly, with terms that protect both the customer experience and your business integrity.

Return policies build trust—but without structure, they can be exploited. Guardrails ensure fairness and protect your brand from preventable loss.

Scaling Jewelry Fulfillment: From Startup to Established Brand

Early-stage jewelry brands often start with DIY fulfillment—and for a while, it works. Packing orders at the kitchen table, handwriting thank-you notes, and dropping off parcels at the post office can feel personal, even charming. But growth changes everything. What once felt manageable becomes a bottleneck, and customer expectations rise faster than most founders realize. Scaling fulfillment isn’t just about keeping up—it’s about staying ahead.

When DIY Stops Working

The first signs are subtle: late-night packing sessions, shipping delays during promos, and a creeping sense that you’re spending more time fulfilling orders than building your brand. Eventually, fulfillment starts to compete with product development, marketing, and customer service for your attention. That’s the signal it’s time to professionalize. If you wait until orders are piling up and customers are waiting, the transition becomes reactive and messy. The best time to plan for scale is before you desperately need it.

Early-Stage Fulfillment Pain Points

For jewelry brands, early fulfillment challenges tend to cluster around a few recurring issues:

- Disorganized inventory – Without clear storage locations, SKU-level tracking, or inventory audits, it’s easy for small items to go missing, get double-counted, or be mislabeled—especially when SKUs look similar at first glance.

- Inconsistent packaging – When every order is packed by hand, it’s hard to maintain uniform presentation. Some packages arrive beautifully; others feel rushed. As volume grows, inconsistency starts to dilute the brand experience.

- Limited shipping options – Early-stage setups often rely on one or two carrier services by default. That likely means some packages are too expensive to ship, others take too long to arrive, and you’re not equipped for anything that falls outside the usual.

- Order accuracy problems – Tiny items, similar-looking variants, and hand-packed workflows are a recipe for errors. A missed item, wrong chain length, or tarnished return doesn’t just cost money—it undermines trust.

- Lack of systemized workflows – As order volume increases, ad-hoc processes break down. Without batching, automation, or clear SOPs, your fulfillment effort becomes reactive, not reliable.

Addressing these issues early creates a smoother path to scale—and ensures that growth doesn’t come at the cost of quality.

The Fulfillment Stress Test: Seasonality

Sales spike around key gifting moments like Valentine’s Day, Mother’s Day, and Christmas, often doubling or tripling order volume overnight. But most young fulfillment operations aren’t built to flex. Instead, they scramble with predictable results: burned-out staff, missed ship dates, piles of make-goods, and frustrated customers. Without scalable workflows, flexible labor, and clear cutoff communication, these surges don’t just cause stress—they damage your brand. The goal isn’t to hustle harder—it’s to build a fulfillment engine that absorbs demand without falling apart.

Sync or Sink: The Importance of Accurate Data

For early-stage jewelry brands, forecasting isn’t just a challenge—it’s a gamble. Run out of a best-seller in Q4, and you lose revenue, repeat customers, and hard-earned ranking. Overstock the wrong SKU, and your cash gets tied up in product that won’t move. As you expand across platforms like Shopify, Etsy, and Faire, the risks multiply. Without synced systems and clear visibility, it’s easy to oversell, understock, or make buying decisions based on feel instead of data—and those missteps don’t just hurt in the moment. They echo for months.

Professionalizing Fulfillment: Build or Outsource?

As order volume grows and early systems start to strain, brands reach a crossroads: keep patching what’s in place or commit to a more scalable solution. That next step usually takes one of two forms. Some brands build out an internal operation with dedicated space, structured workflows, barcode scanning, and trained staff. Others outsource to a third-party logistics provider (3PL) that brings infrastructure, expertise, and scalability from day one. Neither path is universally better—it depends on your growth model, product mix, and appetite for operational complexity. What matters most is making the shift before fulfillment starts slowing you down. With the right systems in place, fulfillment becomes a competitive strength—not a constraint.

Building In-House Fulfillment: What It Takes

For some jewelry brands, keeping fulfillment in-house feels like the natural next step. You know your product better than anyone. You care about the details. And you’re not ready to hand that off. Building your own operation can work—but only if you run it like a full-fledged business unit, not a side project.

Space and Infrastructure

Running in-house fulfillment starts with a physical location. That means dedicated space that’s secure and optimized for packing and inventory movement. Additionally, you’ll need:

- Shelving and bins – A structured shelving system lays the groundwork for an organized and efficient fulfillment space. It ensures that inventory is stored in a consistent and accessible way. This is especially important for small, similar-looking pieces like earrings or charms, where visual identification alone isn’t reliable. A clean, well-mapped layout reduces picking errors, speeds up order fulfillment, and simplifies training as your team grows.

- Product labeling – Every SKU should be labeled clearly and consistently with scannable barcodes. Jewelry pieces are often small, visually similar, and packaged in ways that obscure details, so relying on memory or visual cues leads to mistakes. Labels should include SKU codes, variant info (like size or metal finish), and match exactly what’s reflected in your inventory system. Accurate labeling is the link between your physical inventory and your fulfillment software—and it’s critical for maintaining order accuracy at scale.

- Packing stations – Set up designated, ergonomic workspaces where orders can be packed efficiently and consistently. Each station should be stocked with all the core supplies: mailers, tissue paper, labels, inserts, tape, and any branded elements you include. Everything should be within easy reach to minimize movement and speed up workflow. Well-designed stations reduce fatigue, cut down on packing errors, and help ensure that every order—whether it’s the first of the day or the hundredth—goes out with the same level of care and brand consistency.

- Barcode scanners – Barcode scanning enables fast, accurate verification of picked items before they go into a package. It helps prevent mis-picks, ensures the right variant is packed, and keeps your inventory system aligned with what’s physically leaving the shelf. Scanning also supports quality control and gives you a digital record of every step in the fulfillment process. Relying on visual matching or memory might work at low volume, but it breaks down quickly as order counts rise and SKU complexity increases.

- Label printers – Thermal printers are the industry standard for generating shipping labels quickly and cleanly. They don’t require ink or toner, which reduces maintenance and eliminates messy refills. Labels print fast, stick reliably, and are easy to scan—critical when you’re trying to maintain momentum in a busy fulfillment environment. Investing in reliable label printers helps prevent bottlenecks, keeps your packing stations flowing, and ensures that carriers can scan packages without delays or misreads.

- Scales and measurement tools – Accurate weight and dimension tracking is essential for managing shipping costs, especially when carriers use dimensional weight pricing. A digital scale helps ensure you’re not underpaying (and risking surcharges) or overpaying due to imprecise estimates. Measuring tools—whether built-in or manual—let you confirm package dimensions and make smart decisions about box selection. Consistent, accurate data at this stage helps you avoid billing surprises and stay within budget as you scale.

- Workflow signage and layout planning – A well-organized floor plan reduces confusion and keeps your team moving efficiently. Separate zones for receiving, picking, packing, and returns help prevent cross-traffic, misplaced inventory, and bottlenecks. Clear signage—whether printed labels, color-coded zones, or simple visual markers—reinforces flow and helps new team members get up to speed quickly. Physical structure supports process discipline; it turns your fulfillment space into a system, not just a room with boxes.

The more you grow, the more fulfillment becomes a logistical operation—not just a backroom activity.

Tools and Systems

If you’re serious about running fulfillment in-house, spreadsheets and guesswork aren’t going to work. To match the speed and accuracy customers expect—and to avoid costly mistakes—you need the same level of systemization that any professional 3PL would use. That means putting real infrastructure in place: inventory software, automated shipping tools, and clear processes for tracking and returns.

- Inventory management software – A centralized inventory management system keeps stock levels accurate across all your sales channels. It prevents oversells, supports reordering decisions, and helps ensure the right item is picked and packed every time. Look for software that supports barcode scanning, location tracking, and real-time syncing with platforms like Shopify, Etsy, and Amazon. Without this, even the most organized storage system will start to fall apart as volume grows.

- Shipping label automation – Manually generating labels wastes time and invites errors. Automation tools let you batch-print labels, apply carrier rules, and integrate directly with your order management system. That means less clicking, fewer mistakes, and faster turnaround times. If you’re offering multiple shipping speeds or carriers, label automation also helps ensure the right service level is applied every time.

- Order tracking tools – Modern fulfillment isn’t just about moving boxes—it’s about keeping customers informed from the moment they click “buy.” Tracking tools should sync directly between your shipping management system and your sales channels to provide real-time updates, trigger branded notifications, and feed accurate status info to your customer service team.

- Returns management workflows – Returns are part of doing business, and your systems should make them painless—for both the customer and your team. This includes clear intake processes, condition checks, restocking rules, and visibility into return reasons. Software that integrates returns into your overall inventory and order flow helps close the loop and keep things accurate on the back end.

Without strong systems, errors scale with volume—and so does customer frustration. A mispick here or a missed update there might seem minor early on, but as order counts climb, those small issues multiply into lost time, refund requests, bad reviews, and churn. The right tools don’t just make fulfillment faster—they keep your brand experience consistent, even when things get busy. Investing in systems early is what makes scaling possible later.

Labor and Operational Discipline

At first, you might pack orders yourself—or rely on a small, flexible team that wears multiple hats. But as order volume increases, the margin for error shrinks and the need for structure grows. You’ll need more than extra hands. You’ll need clearly defined roles, consistent training, and repeatable systems. That’s when fulfillment stops being a task and starts functioning like a warehouse operation.

To scale successfully, your in-house fulfillment setup should support:

- Dedicated functional roles – Distinct responsibilities for picking, packing, inventory receiving, and quality control—so nothing gets rushed or overlooked.

- Standardized training protocols – Onboarding processes that teach not just how to fulfill orders, but how to maintain brand standards at every step.

- Staff scheduling and shift planning – Defined labor models that align staffing with peak periods, promo cycles, and seasonal surges.

- Quality assurance checkpoints – Built-in layers of review that catch packing errors, damaged items, or missing components before orders leave the building.

- Performance and error tracking – Systems for monitoring fulfillment accuracy, team productivity, and repeat issues—so you can improve, not just react.

- Documented SOPs – Clear process documentation for every part of the workflow, from intake to packing, to ensure consistency as your team grows.

Running fulfillment in-house at scale isn’t a side project—it’s a second business. The more volume you ship, the more you need operational discipline to keep your brand experience intact.

Benefits of In-House Control

The biggest upside of running in-house fulfillment is control. When you’re managing your operations directly, you have the flexibility to tweak workflows, personalize packaging, and make real-time adjustments as needs evolve. That level of agility isn’t always possible with third-party partners, especially if your fulfillment is highly customized or involves frequent product updates.

With in-house operations, you can:

- Fine-tune workflows on the fly – Quickly adapt to order volume spikes, product variations, or seasonal changes without needing external approvals or waiting for third-party schedules.

- Personalize packaging and presentation – Experiment with different wrapping styles, branded inserts, or unique product bundles that align perfectly with your brand.

- Handle last-minute changes – Accommodate special orders, custom requests, or rush shipments with ease, giving you a competitive edge when customers need fast solutions.

- Maintain high-touch quality control – Keep a direct eye on packing standards, product care, and presentation, ensuring every order meets the exacting standards that your brand promises.

- Implement fast feedback loops – Easily adjust processes based on customer feedback, packaging issues, or performance metrics to keep improving your fulfillment experience.

Done right, in-house fulfillment gives you the power to scale your brand without sacrificing quality or customer experience. It’s about building your fulfillment operations around your brand’s unique needs, not simply executing orders.

Risks and Limitations

The most significant cost of in-house fulfillment isn’t space or equipment—it’s focus. Every hour spent managing staff, fixing pick errors, or troubleshooting delayed shipments is time you’re not spending on marketing, product development, or customer retention. The deeper you go into operations, the harder it becomes to stay focused on the parts of the business only you can drive.

As volume grows, so does the operational burden:

- You own every mistake – There’s no buffer between your customer and your fulfillment errors. A mis-pick, a broken clasp, or a missing package becomes your team’s issue to resolve—quickly and gracefully.

- Fixed costs rise with scale – More orders mean more labor, more packaging, more space, and more overhead—regardless of revenue predictability.

- Hiring and management demands increase – You’re not just building a team; you’re managing time-off requests, retraining staff, and maintaining performance standards under pressure.

- Process gaps create costly delays – Without documented SOPs and accountability structures, small breakdowns snowball into lost time and unhappy customers.

- Operational drag compounds over time – As systems get more complex, even minor inefficiencies can lead to late shipments, inventory mismatches, or burnout behind the scenes.

- It pulls you away from what drives growth – While you’re optimizing a pick path or troubleshooting a WMS sync issue, product launches, customer experience, and strategic planning take a back seat.

Fulfillment done well can be a growth enabler. But fulfillment mismanaged—or simply overextended—can become your biggest constraint.

Bottom Line

If you choose to build in-house, do it with intention. Define the requirements clearly. Treat fulfillment like a strategic function—not an afterthought. Growth doesn’t make things easier. It raises the stakes.

Outsourcing Fufillment: When (and Why) a 3PL Makes Sense

For many growing brands, especially those with lean teams or fast-rising order volume, outsourcing fulfillment offers a smart path forward. A reputable 3PL can deliver the structure, speed, and professionalism of an in-house warehouse—without requiring you to build it yourself. When the right partner is in place, outsourcing fulfillment becomes a growth enabler: it clears operational clutter so you can focus on what you do best.

What a Good 3PL Brings to the Table

The best 3PLs act as an extension of your brand, combining robust infrastructure with seasoned operational discipline. Instead of starting from scratch, you tap into systems that are already built to scale. Consider:

- Space and scalability – 3PLs operate out of large, purpose-built warehouses designed for efficient storage and order flow. That means no more scrambling for shelf space or repurposing office areas. As your business grows, the facility—and its team—scales with you. No new leases. No renovations. No delays.

- Professional staff and workflows – Fulfillment centers run by 3PLs rely on trained warehouse associates who follow standardized picking, packing, and quality control procedures. You’re not managing labor or worrying about shift coverage—they are. That consistency reduces errors, maintains speed, and ensures your customer experience holds up under pressure.

- Integrated technology – Most 3PLs provide a portal or dashboard where you can view orders, monitor inventory, track shipments, and access reports in real time. Their systems are designed to integrate with your eCommerce platforms—like Shopify, Etsy, or Amazon—so you maintain visibility without managing every task yourself.

- Shipping expertise and cost savings – A 3PL ships thousands of packages a day and often negotiates bulk discounts with major carriers. That means better rates, faster delivery options, and fewer surprises. They also handle rate shopping, dimensional weight calculations, and label generation—automatically.

- Returns handling and reporting – The right partner doesn’t just send out orders—they help manage returns efficiently. They’ll log returned items, assess condition, and restock what’s salvageable. Many provide reporting on return reasons and trends, giving you valuable insight into product or sizing issues that might be affecting customer satisfaction.

When Outsourcing Works Best

Outsourcing isn’t just about handing off boxes. It’s about getting strategic leverage. Here’s when it’s usually the right move:

- You’re shipping 30–100+ orders per day and it’s becoming a drag on your core team.

- You’re expanding sales channels and need consistent fulfillment across platforms.

- You want to add more professionalism to your packaging without reinventing your process.

- You’re planning for growth but don’t want to invest in infrastructure upfront.

- You’re spending too much time troubleshooting pick errors, shipping glitches, or late deliveries.

If any of that sounds familiar, it might be time to explore outsourcing—not as a last resort, but as a strategic upgrade.

Potential Tradeoffs

As with any partnership, outsourcing comes with tradeoffs:

- Less hands-on control – You’re trusting someone else to represent your brand through the unboxing experience. If you have highly customized or fragile packaging, you’ll need to choose a partner who can meet your exact standards—or be willing to adapt.

- Minimums and onboarding costs – Most 3PLs have minimum order volumes or monthly spend requirements. There’s also a learning curve as you integrate your systems, ship inventory, and configure workflows. This isn’t an instant plug-and-play solution—it’s a transition that takes coordination.

- Billing complexity – 3PL pricing structures can include storage fees, pick and pack fees, shipping surcharges, and special project charges. A great 3PL will be transparent and communicative—but you still need to read the fine print and ask the right questions up front.

Choosing the Right Partner

Not all 3PLs are created equal. Look for one that understands your product category and order volume, not just the logistics business in general. The best partners:

- Are responsive and transparent in communication

- Offer flexible packaging options without nickel-and-diming

- Let you start lean and scale as needed

- Provide real-time inventory tracking and order visibility

- Act like an operational ally—not just a vendor

Bottom Line

Outsourcing fulfillment isn’t a shortcut—it’s a strategic shift. If fulfillment is holding your team back, if quality is starting to slip, or if you’re spending more time putting out fires than building your brand, it’s time to consider a 3PL. With the right partner, you get professional-grade fulfillment without the overhead—and the freedom to double down on growth.

Why You Can’t Trust Just Any 3PL

Not every fulfillment operation is built to handle the unique challenges of fashion jewelry. As your brand scales, the risks tied to poor packing, mispicked items, or inconsistent presentation grow with you. The right fulfillment partner doesn’t just ship your product—they protect your brand, preserve your margins, and help you deliver a consistent customer experience at scale.

Here’s what to look for when evaluating your options:

- Precision with small, lightweight items – A fulfillment partner should be comfortable working with products that require fine-motor handling—tiny clasps, delicate chains, plated surfaces, or layered pieces. Whether your SKUs ship in gift boxes, branded envelopes, or small pouches, the team handling them should understand how these materials move and how easily they can be scratched, bent, or tangled.

- Comfort with high SKU counts and similar variants – When you sell jewelry, your catalog might include hundreds of SKUs—even for a relatively small collection. Managing color, finish, size, and material variations requires systems that minimize human error. Your 3PL should have strong inventory controls, barcode scanning, and workflows that reduce the chance of mix-ups.

- Packaging that matches your brand – The unboxing experience matters, even at lower price points. A good fulfillment partner will support branded materials—like tissue paper, logo cards, anti-tarnish strips, or seasonal inserts—and ensure they’re packed consistently. They should also help balance presentation with shipping efficiency, keeping things beautiful and

- Reliable returns and restocking workflows – Returns are part of the jewelry category. Look for a fulfillment partner that offers clear workflows for inspecting, sorting, and restocking returned pieces—without damaging the customer experience or slowing down your operations.

Jewelry fulfillment is its own category. It may look simple from the outside—small, lightweight products—but the reality is far more complex. When precision, presentation, and product care are non-negotiable, not every fulfillment setup will cut it.

How to Smoothly Transition to a 3PL

Switching to outsourced fulfillment is a big move—and one that can unlock massive growth if handled well. But it’s also a common failure point. Brands rush the handoff, skip documentation, or assume the 3PL will just “figure it out.” The result? Sloppy packouts, missed orders, and customer service overload.

A smooth transition doesn’t happen by accident. It happens when you approach the move like a project—with clear expectations, strong inputs, and realistic timelines.

Start with Clear Documentation

Before the transition begins, turn your existing knowledge into a documented, repeatable system. If you’ve been relying on memory or informal training, now’s the time to codify the essentials.

Your documentation should include:

- Packout instructions by SKU or collection – Define exactly how each item should be packed, including jewelry cards, pouches, tissue, stickers, tape, and box type.

- Photos of correctly packed orders – Provide multiple angles of properly assembled orders for visual reference during training and QA.

- Packaging rules by product type – Spell out which products require rigid boxes vs. soft mailers, anti-tarnish materials, or other protective elements.

- Insert logic – Note when to include thank-you cards, care guides, discount codes, or seasonal promos—and how they should be matched to products or campaigns.

- Gift message formatting – Clarify where and how to place printed notes, hand-written messages, or alternate gift presentations.

- Seasonal or event-specific workflows – Detail how packouts should change for holidays, influencer mailers, subscription kits, or high-value customer tiers.

- Branded vs. discreet packaging logic – Define when to apply branding (or remove it), especially for surprise gifts or sensitive shipments.

If something lives in your head—or is “just how we do it”—it needs to be in writing. The more your 3PL has up front, the more they can execute your brand experience without constant handholding.

Clean Up Your Inventory

Before you ship a single unit to your new 3PL, make sure your inventory is clean, organized, and accurate. Transferring messy data—or disorganized physical stock—just exports your current problems into a new system.

To prepare your inventory for a smooth transition:

- Verify SKU accuracy – Confirm that each product has a unique, standardized SKU that matches what’s listed in your eCommerce platform and inventory system. No duplicates, no guesswork.

- Eliminate “ghost SKUs” and dead variants – Remove inactive, unpublished, or outdated SKUs that could confuse pickers or inflate inventory reports.

- Standardize barcode labeling – Ensure every unit is labeled with a scannable barcode that maps back to a specific SKU—especially important for similar-looking pieces or small components.

- Count and reconcile physical inventory – Perform a physical count of all units you plan to transfer, and match that against your digital inventory. A mismatch here causes downstream chaos.

- Flag fragile, high-value, or non-resellable units – Set aside damaged items, return stock, or open-box inventory so only clean, sellable units are sent to the new facility.

- Use consistent labeling on physical cartons – When you ship inventory to your 3PL, each carton should be clearly marked with SKU names, quantities, and condition notes—so receiving doesn’t become a guessing game.

A clean inventory handoff builds trust, speeds up onboarding, and prevents the most common root cause of early fulfillment errors.

Map Your Fulfillment Logic

Your 3PL won’t know your product the way you do—so if your fulfillment relies on internal judgment calls or habits, those need to be systematized before the handoff. Think like an ops lead, not a founder.

Your fulfillment logic should account for:

- Packaging rules by product type – Spell out which items get pouches, jewelry cards, boxes, or branded mailers—and when to use each. Avoid catchalls.

- Channel-specific workflows – If your Etsy orders get one insert and your Shopify orders get another, make that logic explicit. Marketplace rules vary—and so should your packouts.

- Gift and message handling – Define when and how gift notes should be printed, where they go in the package, and whether anything changes based on platform or price point.

- Variant-level requirements – Clarify if different finishes, lengths, or sizes require distinct packaging or handling (e.g. longer chains need extra padding or box support).

- Subscription or kit logic – List out what SKUs get bundled, how they should be packed together, and whether to hold, release, or schedule them.

- Tiered customer experiences – If your high-value customers get upgraded packaging, extra inserts, or loyalty gifts, build that into your logic—not your wishful thinking.

- Seasonal or promotional changes – Include guidelines for Mother’s Day gift wrap, Black Friday insert swaps, or influencer kits tied to launches.

If you can’t write it down, your 3PL can’t execute it consistently. The goal isn’t to micromanage—it’s to create a system your brand can grow on.

Align on Service Expectations

Even with great documentation and clean data, things can still go sideways if your expectations and your 3PL’s reality aren’t aligned. Before you go live, set the terms of engagement—so both sides know what good looks like.

Key areas to align on:

- Turnaround time – Define your expectations for how quickly orders should ship (e.g. same-day by 2pm ET, next-day fulfillment during peak periods, etc). Get agreement in writing.

- Receiving SLAs – Clarify how long it will take the 3PL to receive, count, and stock inbound inventory—especially if you’re working with overseas manufacturers or tight launch schedules.